SPECIALIZE INSTALLATION WORKS

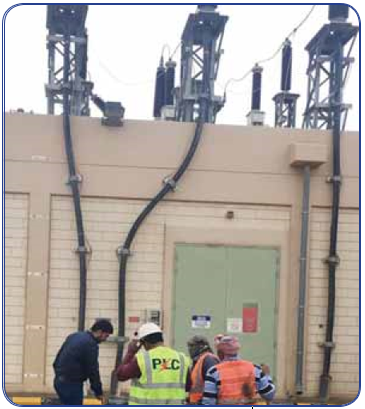

Power Lines Contracting Company carry out all manner of installation works from All sizes of power & control cabling and Switch gear works Under SEC supervision and Client Consultants as well as private sectors. This includes the supply and installation of all high and low voltage switchgear, transformers, cabling and earthing Works.

All types of installation works associated with distribution networks from package substation installation Power & control cabling and Switches Gears works, private networks, Grid transformers, network ca bling and earthing/lightning protection for SEC projects and Private Clients.

INSPECTION

Power Lines Testing Division carries out for many of its clients regular Cables, OHL & Substation ins pections.

This work consists of visual inspection of all substation equipment,Cable Terminations, checking of the building security, testing of transformer insulating oil samples, and, where fitted, replacement of transformer and foundation, earthing system. Also Power Lines Testing Division employs a full-time dedicated team of inspectors, specializing in the inspection of electrical power equipment installations with emphasis on BSEN 60079, (electrical equipment in hazardous areas).

These inspections are designed to complement our preventative maintenance programme by high lighting potential problems. A fully computerized records and reporting system is used for inspection activities.

TESTING & COMMISSIONING SERVICES

This facility is complemented by our range of other testing services available, which include the following: As per SEC & IEC Standards.

• All Types of Cable Testing 13.8 kv,33kv & 132kv.

• HI pot Testing.

• Testing – both primary and secondary CT›s.

• Earth Installation Testing – as per SEC Standards.

• Power Factor Correction Equipment Testing and installation.

• PD Test for 132 kv Switch Gear & Cable Circuits.

• Power Transformer testing, Winding, Insulation, Dielectric

Our extensive experience with a vast array of substations allows. our team to provide attention to detail while ensuring the best possible quality and system reliability. SERVICES INCLUDE:

• Cable supply, installation, Termination and Testing.

• Electrical power systems, protection panels and distribution switchgears.

• Power &Control system installations.

• Power Transformer installation and testing including oil filtration and treatment.

• GIS installation and testing including gassing and degassing.

SKILLED AND AUTHORIZED PERSONS

Power Lines Contracting Testing Division employ a number of fully trained Authorized persons who carry out all duties relating to the safe operation and running of our client high voltage / Low voltage .systems/networks.

These duties range from a full on site presence to daily requirements Power Lines Contract Testing Division are also capable of tailoring training courses for you and your staff. SAP Training includes safety from the system, safety documentation Permit to works, Sanction. for test, switching schedules and operation of switch-gear For clients with private networks we offer a Senior Authorized Person call out facility with a response time of between 2 to 4 Hours. Our Engineer will attend site and assist in determine cause of failure and restoration of supply. Power Lines Testing Division are experts in this reactive problem solving. giving you both peace of mind and confidence that your supplies are safe in our hands.

CABLE FAILURE

Buried cables can, at any time, be subject to damage. Mechanical excavators are the most obvious but cables can also sustain damage from ‘moles’, trench-cutting machines, tunneling rodents, even from someone driving in a tent peg! Damage sustained may not cause the cable to fail immediately . – some cables have lasted a number of years after being damaged. Some cables may fail without having been damaged.

When a cable fails, someone, somewhere loses their electrical supply. We can provide a cable fault lo cation service that includes:

• Taking full control of electrical safety.

• Locatiing, pinpointing the position of the fault.

• Cable Fault Location.

• Cable Sheath Location.

• Excavation Works.

• Repair of the cable.

• Testing of the repaired cable and return to service.

• Reinstatement of the ground service.

MAINTENANCE

Power Lines Contracting Testing Division have tailored our Maintenance reports to ensure all key parts are inspected and recorde d allowing for tend a analysis and carried out by Power Testing Ltd is recorded on our equipment specific report sheets. Our report sheets have been designed to meet and exceed manufacturers’ recommendations for carrying out electrical maintenance in accordance to Standards.

All reports are entered onto our computer database and stored so that when required previous reports may be viewed within seconds.

We have staff trained and conversant with equipment ranging from distribution boards up to 132kV Switch Gears and main tain a library of manufacturers’ information regarding electrical distribution equipment. Indeed, many modification and repair circulars issued by manufacturers to our clients are passed on to us, as it is usually Power Lines Contracting Testing Division that will be carrying out any modifications or checks.

HAZARDOUS AREA INSPECTION

Overview

Gases, vapours, mists and dusts can all form explosive atmospheres with air.

Hazardous area classification is used to identify places where, because of the potential for an explosive atmosphere, special precautions over sources of ignition are needed to prevent fires and explosions.

General Summary

PLC ensure intrinsically safe equipments remains in satisfactory condition for use within a hazardous area.

As it is critical to create either a continuous or periodic inspection interval. According to IEC 60079-17 [ed4.0], there are five different inspection methods that ensure the continued reliability of plant equipment:

– Initial

– visual

– close

-detailed

-and continuous supervision.

While all but continuous supervision are periodic checks, continuous inspection requires your organization to frequently inspect, service, care for, maintain, and be trained on current and future hazardous area installations. Continuous inspection also does not remove the requirement for scheduled periodic inspections. By relying primarily on a periodic inspection approach, your organization will need to maintain a proactive schedule to ensure visual, close and detailed inspections are occurring at appropriate intervals, taking into account the installation application, equipment deterioration over time, and manufacturer’s guidance. The interval between detailed inspections should not exceed three years without seeking expert advice for fixed installation applications and one year for moveable (portable) equipment applications. Once the interval is determined, each installation should be subjected to additional interim sample visual or close inspections to support .PLC proposed detailed inspection interval. Setting the proper maintenance schedule for your intrinsically safe equipments helps promote a strong understanding of the condition of hazardous area equipment over its life. PLC ensures helps to ensure that you provide a safe environment for your processes, business and employees.

OTHER SERVICES

• Cable & OHL Route Surveys.

• Land,Sites Surveys, Soil Investigation

• Inspection Lightning Protection system

• Power Quality analysis to SEC standards

• LV,MV,HV Cable identifying and spiking

• Preparations of Designs& Drawings

• Operation and Maintenance Contracts& Manuals

• Private Projects, Clients Contracts • Cable Jointing, Termination , Link Boxes

• Emergency Call Out Facility, Faults, Cable repairs

Wherever you are, whatever you do, Power Lines Contracting Testing Division can provide the necessary services on time. 24 hours back-up services can be provided.

Power Lines Testing Division has tailored its services to meet and exceed client expectations. Our years of experience put us at the fore front of our chosen industry sector. We pride ourselves on solving client problems and are known throughout the industry for our im mediate reactive emergency services

Parallel this with our excellent project management and planned works management we make excellent partners in servicing your elec trical distribution system and ensuring your electrical supply.

|

|